Anode Service is specialized in supplying anodes to the maritime industry. We offer mainly aluminium and zinc anodes for new build projects and maintenance jobs. Besides making anodes we have a strong network with other European anode manufacturers. In a demanding market where time is always tight we promise a fast delivery against a good price and best anode quality.

All types of standard anodes and more

Anode Service delivers all types of aluminium and zinc anodes in every size and shape with bolt-on or welt-on montage possibilities. Our anodes are always produced in Europe and tested on alloy and composition which make them more effective than wholesale anodes with untraceable production background. Next to the standardized anodes with fixed sizes we deliver also measure made anodes which can meet all sizes and shapes required.

The effective use of aluminium anodes

In many maintenance plans zinc anodes are integrated as the standard prevention against corrosion. Zinc anodes are mainly used for ships that navigate in seas and oceans where there is saltwater. However the use of aluminium anodes has proven to be minimal as effective as zinc anodes with less aluminium needed for the same protection that zinc offers. There can be used a reduced amount of anodes in the cathodic protection plan when using aluminium. An aluminium anode with the same sizes as a zinc anode is lasting 25% longer. Besides the economic benefits aluminium anodes are more environmental friendly than zinc anodes because they lack the containment of cadmium.

Anodes for anti-fouling

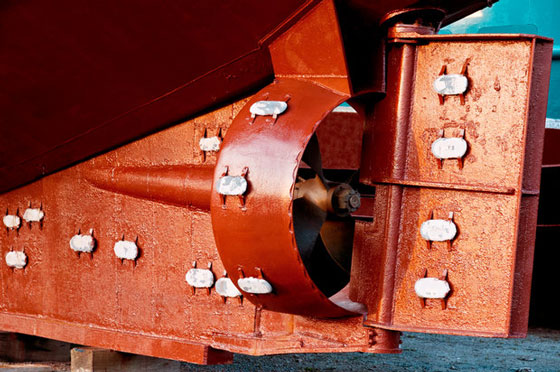

Anti-fouling anodes are necessarily to prevent cooling systems from biofouling and marine fouling. The more common name for these anodes are MGPS (marine growth preventing system). With the use of copper and aluminium anodes combined, box cooler systems are protected against corrosion and fouling. Harmless for the environment, copper and aluminium anodes are effective in all temperatures and at all depths.

Practical application

Anodes are used on the ship's hull, rudder, propeller, bow, and in the box coolers The alloy of an anode is specifically composed to make the aluminium, zinc or copper active and effective. When the anode is welded or bolted to the ship it will protect the steel by being the more active alloy. Connected to the ship, the anode sacrifices itself, where the water functions as the electrolyte. In time the anode will dissolve slowly in order to be renewed in the next dry dock routine.

Maritime market

As we are based in the region of the Harbour of Rotterdam we work with nautical costumers from around the globe. Our growing customer base of Ship-owners and Shipmanagement companies know how to find us when it comes to fast deliveries, efficient communication and good anode quality. Because every request for corrosion and fouling protection is asking for a different routine we know how to adjust our service to the different requests in an effective way.