Comment

Cruise operators take retrofits on-voyage

Angelo Soraci, projects director at Bluestone Group, explains how cruise operators are adapting retrofit strategies and lessons learned from on-voyage execution.

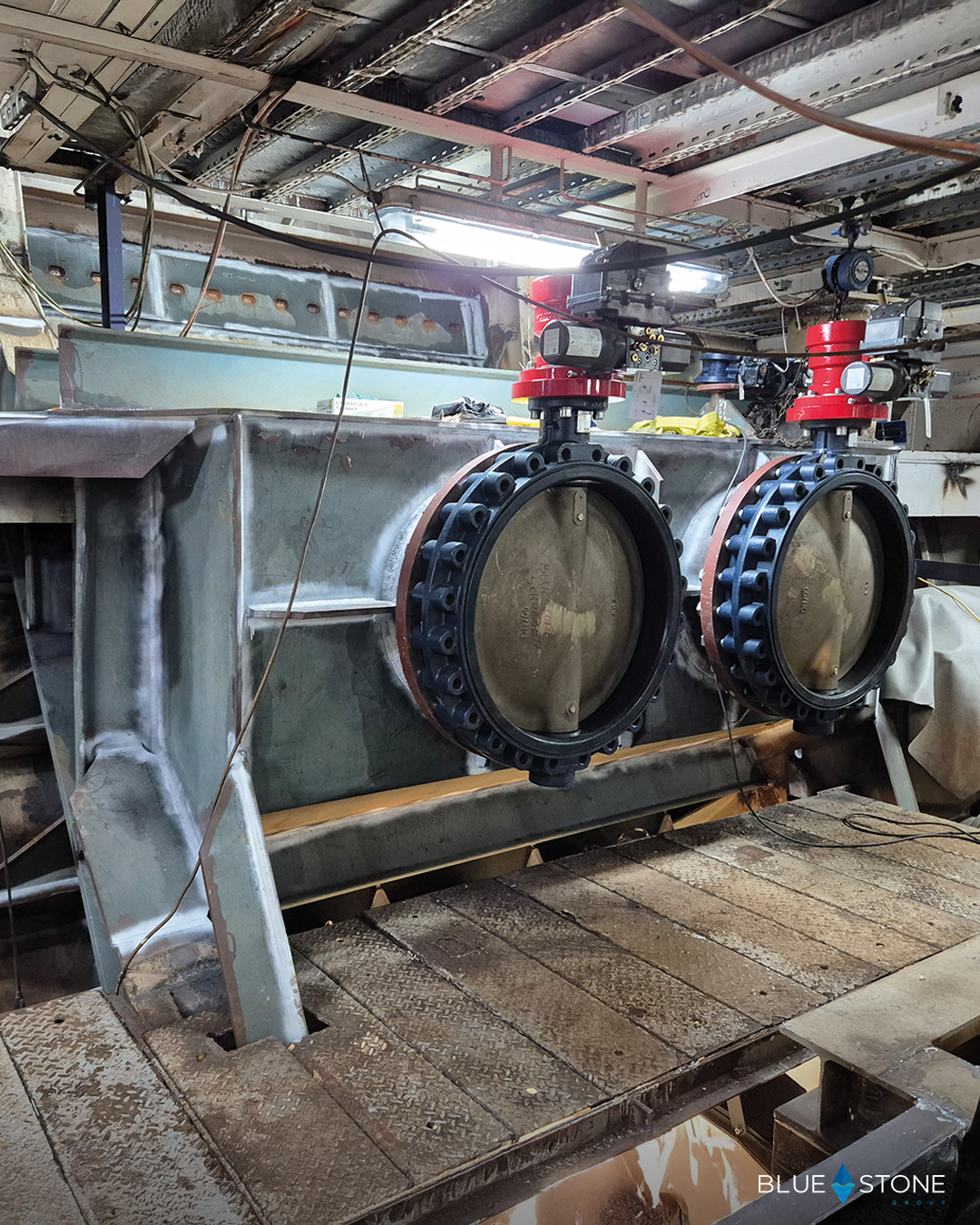

Main image:

As shipyard capacity tightens and environmental targets advance, cruise operators are rethinking retrofit execution. For a sector built on precision scheduling and high service expectations, the challenge is clear: improving efficiency, safety, and sustainability without disrupting operations.

Angelo Soraci, projects director, Bluestone Group

According to ABS and Maritime Strategies International, shipyards may fall short of retrofit demand before 2030, while Clarksons Research reports a 7% rise in repair activity this year, far outpacing fleet growth as ageing vessels reach key milestones and owners accelerate energy-saving upgrades.

Adding to the complexity, the IMO’s delayed Net-Zero Framework leaves owners without a definitive regulatory timeline. For now, energy efficiency remains the most practical and cost-effective lever available.

The World Bank’s Keys to Energy-Efficient Shipping report shows operational and technical efficiency measures could cut emissions by around 40% by 2030 and reduce transition costs by roughly $220bn annually – half of which is cost neutral through fuel savings.

Efficiency without downtime

Cruise operators are particularly impacted by extended yard stays. Every day off-hire means lost revenue and disrupted schedules. Retrofit demand is also rising as drydock intervals shorten from 4-5 years to 2-3 years, driven by ageing fleets, new technology, regulation, and passenger expectations for upgraded amenities and greener voyages.

Cruise ships are designed for continual improvement, requiring partners who can adapt to evolving needs.

While drydock remains essential for major projects, tighter windows are driving more in-operation retrofits. Energy-saving retrofits are most in demand, particularly for heating, ventilation, and air conditioning, which consume significant onboard power. Post-Covid-19, demand for these upgrades surged, shifting focus from pollution control. By improving these systems, operators cut fuel use and emissions while enhancing performance.

Cruise ships are designed for continual improvement, requiring partners who can adapt to evolving needs. Upgrades are increasingly engineered for on-voyage delivery, short port calls, or minimal drydock time, targeting hotel-load systems (HVAC, lighting, automation, and water treatment), directly influencing energy demand and passenger experience.

Executing complex retrofits in active service demands meticulous coordination. Bluestone delivers projects under a structured EPC framework combining naval architecture, marine engineering, and site management.

Detailed planning, regional material sourcing, and digital progress tracking maintain transparency for owners and consistent quality worldwide, with modular prefabrication and sequenced installation minimising downtime. Supported by dedicated project managers, naval architects, and engineers, every task is executed safely, on schedule, and to the highest standards.

Precision in practice

This precision has been proven across over 25 HVAC chiller replacements for major operators, including several Carnival Corporation brands, Grandi Navi Veloci, and NCLH. 45-tonne chillers can now be replaced within 72 hours via side-shell openings, integrating variable-frequency drives and control systems to improve efficiency and reduce electrical load.

The same disciplined approach supports fleet-wide retrofits. Examples include 5 air-lubrication systems installed within 45 days through combined drydock and at-sea execution across three countries; 74 UV-C lamp retrofits completed in under a month to improve air quality and hygiene; and multi-vessel, multi-location energy-efficiency retrofit programmes.

Further examples include micro auto gasification system (MAGS) waste-to-energy installations completed in 20 days, phased exhaust gas cleaning system (EGCS) and selective catalytic reduction (SCR) retrofits, ballast-water and advanced wastewater systems, and passenger-focused projects like waterslide installations – all delivered with minimal disruption.

Each project is executed in “ghost mode”, completed discreetly and handed back clean, tested, and certified. By maximising every access window, multiple scopes can be integrated within a single maintenance period, reducing cumulative downtime and cost.

Retrofit strategy can no longer be reactive. The most forward-thinking owners treat upgrades as part of a continuous improvement cycle rather than one-off events. Smaller, well-timed interventions can be phased throughout the operating cycle, spreading cost and technical risk while keeping vessels compliant and commercially active.

By combining engineering, procurement, and construction within one framework, and feeding lessons learned from completed projects into future planning, operators can forecast and schedule interventions years in advance, compressing yard time when unavoidable and eliminating it where possible. Each improvement builds on the last, gradually modernising the vessel without disrupting service.

Navigating what comes next

The retrofit market is evolving from single-system installations to integrated efficiency programmes, with near-term growth in hybrid readiness, shore-power integration, and advanced monitoring systems, alongside continued modernisation of hotel-load infrastructure. Pollution-control retrofits, including wastewater and blackwater treatment, are also expanding under stricter environmental requirements.

Progress will not come from waiting for the perfect decarbonisation pathway but from doing the essentials well.

For cruise operators, the stakes are high: emissions face greater scrutiny, regulation is tightening, and passenger expectations continue to rise. Meeting these demands requires partners who understand that in cruise, safety, schedule, and guest experience are as critical as emissions reduction.

The retrofit challenge is not just about installing new technologies; it’s about protecting revenue, safeguarding continuity, and building resilience amid new, systemic constraints on our industry. By embracing on-voyage execution and lifecycle planning, operators can turn retrofit pressure into opportunity – achieving measurable efficiency gains today while preparing for future fuel transitions.

Progress will not come from waiting for the perfect decarbonisation pathway but from doing the essentials well: planning early, engineering for operations, and executing with precision. In a business where every sailing counts, that discipline is what keeps the fleet and the transition moving forward.