Company Insight

Sponsored by Martechnic

Oil Quality Management: 25 Years of Tradition and Innovation

In March 2022 Martechnic is celebrating its 25th company anniversary. Since its founding in 1997 as a family-owned business, Martechnic has become a leading expert in oil quality management and succeeded to secure its international recognition and a solid niche market position of technical solutions for condition monitoring of fuel, lube and hydraulic oil.

A cornerstone of the business’s philosophy and practice has been the combination of two principles: tradition and innovation. Using the benefits of past knowledge and experience, Martechnic focuses on innovative technology and offers its customers oil test analysis equipment for on-site application.

The company designs, develops and manufactures a wide range of high-quality products: oil test devices and oil test kits, intelligent oil sensor technology, oil sampling bottles and ultrasonic cleaning equipment. A global network of Martechnic’s partner companies provides for 24-hour customer service, quick order processing and worldwide delivery.

Oil Analysis for Condition Monitoring of Fuel, Lube and Hydraulic Oil

Company’s Vision and Mission

For 25 years Martechnic’s oil analysis solutions have been an effective tool to support smooth running, optimal and reliable performance as well as cost-effective maintenance of on-board machinery, engine and equipment. The adoption of oil condition monitoring practices or in-service oil testing allows engine operators to routinely measure, monitor and analyse crucial oil parameters directly on board a vessel. Thereby any off-specification issues (e.g., degradation of the oil quality or abnormal wear) or changes in the oil condition (e.g., contamination) can be detected before an actual problem occurs. Such an early-warning mechanism enables adequate preventive maintenance actions: continuous information on engine performance can help fixing relatively minor problems to avoid possible costly engine failures, major damages and uncontrolled downtimes.

Successful implementation of oil condition monitoring programs can also help to comply with international norms and standards of environmental protection aiming at minimizing environmental impact, supporting sustainable development and saving precious resources.

Areas of Expertise

Oil Test Devices and Test Kits

A reliable method of oil analysis program is the oil condition monitoring by regular testing with portable oil test devices and test kits. Independent of standard laboratory analysis, engineers and/or end-users can perform an on-site oil analysis to check essential parameters of fuel, lube and hydraulic oil such as water content in oil, alkalinity reserve (BN), viscosity, density, insolubles as well as iron content, cat fines, stability, compatibility and many more. The oil testing equipment is easy to use even for untrained operators, provide instantaneous and high-accuracy test results as well as the possibility of their direct assessment.

Apart from immediate identification of any ongoing problem with the oil quality/ oil condition, a significant advantage here is the possibility to schedule the oil analysis at regular intervals of choice (weekly, fortnightly or monthly) depending on particular application environment and to collect the data for a trend analysis. Tracking the changes in the used oil quality/ condition in comparison to initial reference data can help to make a prognosis and accordingly to plan efficiently on necessary maintenance time, e.g., to extend the maintenance intervals or oil changes.

Innovative oil analysis test devices in line with Industry 4.0–concept facilitate massively the testing process and deliver quick and precise digital test results.

Oil Analysis with Intelligent Sensor Technology

The condition monitoring of the in-service oil can be organised through installation of in-line intelligent sensor technology. Oil quality/ condition is constantly analyzed with sensors and any small changes are immediately registered, be that contamination, oil degradation over time or signs of wear.

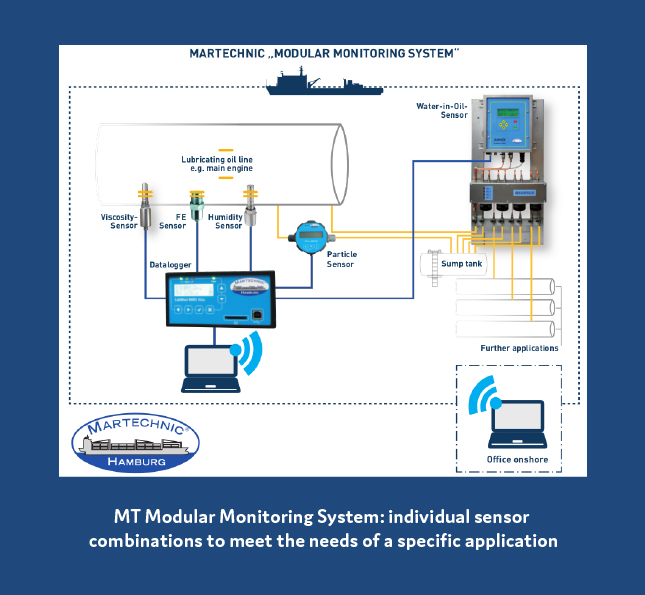

Martechnic’s innovative “MT Modular Monitoring System” contains different sensor types for a customer-specific field of application (M/E, generators, gearboxes, hydraulic systems etc.) and an oil parameter to be monitored. The sensors can be installed individually or combined and connected to the special display unit “Datalogger” for continuous data recording and assessment. Automated alerts provide immediate notification when anomaly is identified. Therefore, the maintenance operators can take efficient measures to tackle an issue at the pre-alarm level during the uninterrupted operation process of machinery.

Optimized condition-based maintenance intervals, minimized downtime, increased productivity, real-time statistics/ trendline and reduced oil sampling are among the key benefits of the advanced sensor technology.

Oil Sampling

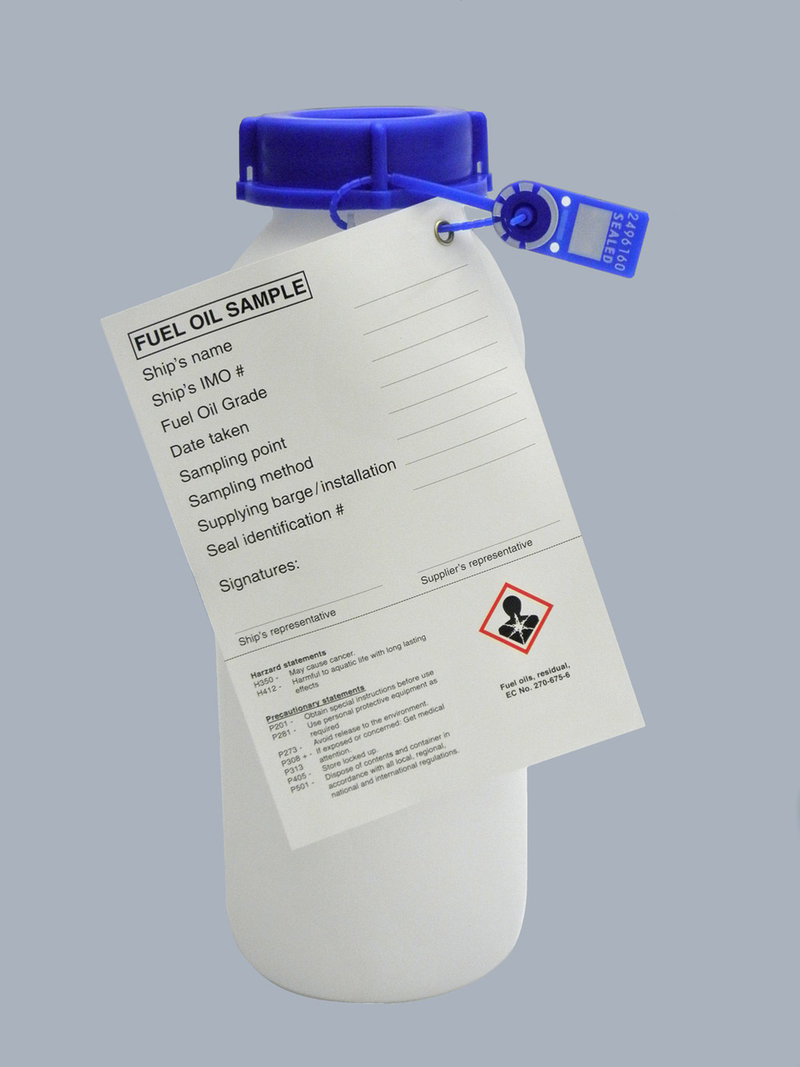

Proper oil sampling and representative oil samples are the requirement for any valuable oil analysis program. Martechnic offers its customers different sample bottles and cubitainers for fuel, lube and hydraulic oil that are equipped with a tamper-evident technology. An in-line Drip Sampler enables easy and accurate collection of MARPOL fuel oil samples during bunkering. A special attachment mechanism of cubitainers to Drip Samplers through a uniquely numbered seal strip reliably protects from any external contamination of a fuel oil sample.

Fuel Oil Sample Bottle with a tamper-evident solution

Drip Sampler and cubitainer attached with a tamper-evident seal

Ultrasonic Cleaning Equipment

Heavily fouled machine parts with difficult-to-reach areas can be quickly and efficiently cleaned with the help of ultrasonic cleaning technology. The ultrasonic cleaning is environmentally friendly method which provides gentle cleaning and prevents from any scratches or damages to the complexly shaped equipment. Martechnic offers standard and tailor-made ultrasonic cleaning tanks, ultrasonic generators with external transducers for cleaning tanks and ultrasonic cleaning liquid.

All images credit: Martechnic GmbH

Contact details

Martechnic GmbH

Adlerhorst 4,

D-22459 Hamburg, Germany

Tel.: +49 (040) 853 128 0

Fax: +49 (040) 853 128 16