Technology

Shipshape hulls: inside new robotic cleaning technology

Keeping a ship hull clean offers many benefits for the overall running of the vessel and the environment. Shipshave has a new robotic solution to keeping hulls clean. Frankie Youd investigates the technology.

Image: copyright

Cruising the ocean from port-to-port causes ship hulls to wear over time, collecting a variety of barnacles, algae, and other marine organisms.

Hull cleaning to remove marine debris and species built up over time traditionally takes place at port between voyages. However, a severe build-up requires harsher cleaning processes that can degrade hull hydrodynamics, which can lead to increased fuel consumption and CO2 emissions.

Norwegian company Shipshave has developed the ‘In Transit Cleaning of Hulls’ (ITCH) solution to this issue. ITCH uses a robotic semi-autonomous device to clean hulls while ships are at sea, with no help from third parties. It allows frequent cleaning, which optimises and maintains hull efficiency.

On 3 February, maritime technology media outlet Digital Ship hosted a webinar, ‘Using robots for in transit hull cleaning’, which showcased a semi-autonomous robot created to clean ship hulls. Operated by seafarers at sea – rather than scheduled in port – this new solution improves a ship’s performance and offers environmental benefits.

Clean hull, clean sailing

A build-up of marine organisms on a ship’s hull reduces the overall performance of the vessel and can cause several maintenance issues. If frequent cleaning does not occur a clumpy slimy layer, known as biofilm – a layer of microorganisms and bacteria – will build up on the ship’s hull.

In severe cases where cleaning has not occurred for some time hulls can begin to accumulate barnacles and seaweed which can amount to a significant weight increase for a ship. The additional weight of these marine stowaways, combined with the weight of the hull coating, results in increased drag for the vessel which can cause fuel penalties.

Frequent cleaning of a ship hull offers a variety of benefits, such as reduced operational costs due to fuel savings, which in turn reduces the amount of greenhouse gases produced.

Less invasive cleaning methods also increase the longevity of antifouling coatings applied to ship hulls, further reducing hull cleaning time. It also reduces biofouling, the process by which invasive aquatic species are introduced into new environments.

Ships have been identified as a key culprit for this, with an increasing number carrying invasive species into new waters, resulting in native species being outnumbered. Frequent cleaning of ship hulls removes this biofouling growth, reducing the risk of invasive species sneaking into native waters.

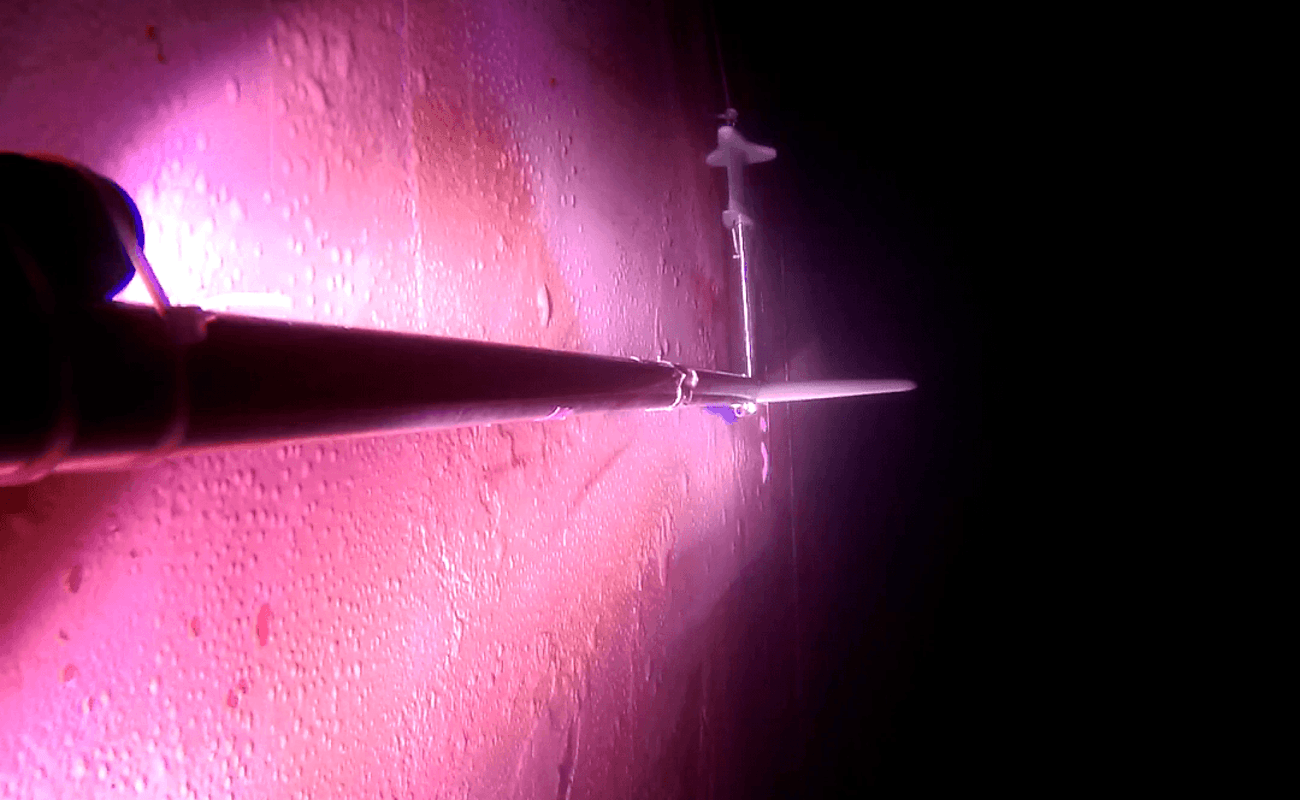

The ITCH autonomous robot arm can be operated by one person. Credit: Shipshape

Robots to the rescue

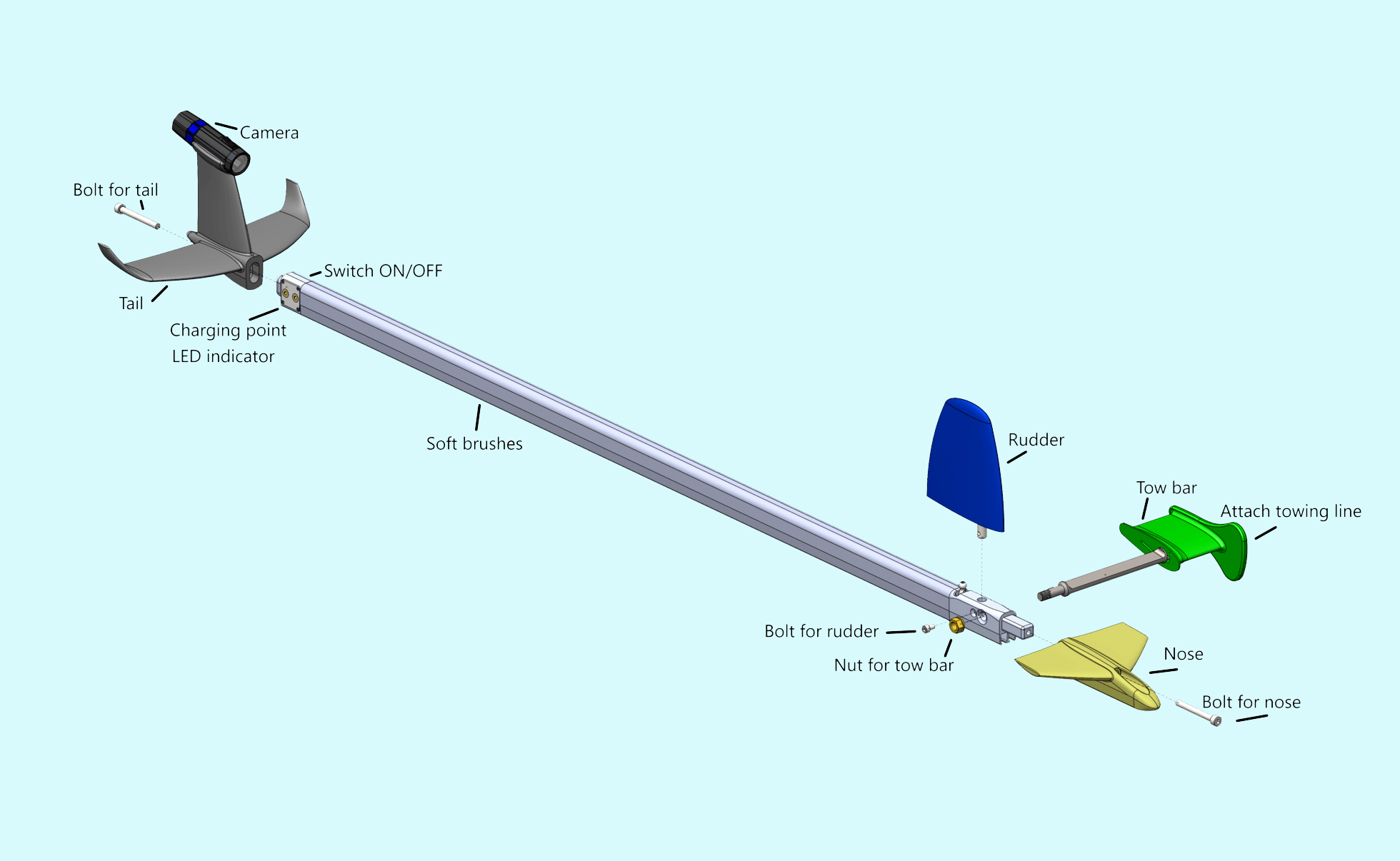

The ITCH solution compromises a semi-autonomous hull cleaning robotic arm, which is tethered to a winch on the forecastle deck of the ship. The arm uses propulsion energy to stay attached to the hull while swiping up and down along the ship’s hull.

Using soft brushes, the hull is cleaned underwater using a defined pattern with controlled brush force, keeping the hull clean without damage.

Itch weighs 50kg and comes in two parts that can be easily carried by crew members. Before use, the crew needs to configure the robotic upper arm and lower depth settings using the ITCH application.

Shipshave sales and marketing manager and co-owner Eirik Elde commented in the webinar: “We deliver two types of winches: one electric frequency control winch and one pneumatic one for vessels with explosive cargoes.

“We maintain that it should be a two-man operation although it can easily be done by one person – one should operate the winch and one person should monitor the progress along the side of the vessel.”

The captain was able to note a 5-6% speed increase... it translates into a good fuel saving.

After these settings have been configured the robot can be deployed into the sea via the winch so that the vertical side of the ship can be cleaned. Once this is complete the robot can be retrieved from the sea and switched over to the other side of the hull to repeat its cleaning mission.

The arm is equipped with an integrated data capture system that records the robot cleaning process and can be viewed and evaluated via the ITCH application.

The robot cleaning process is also much faster than traditional cleaning.

Discussing speed trials that the company has carried out using the technology, Elde said: “The first trial that we did was on a platform supply vessel, and we attempted to go for a voyage in two directions, with counter current and wind at full speed.

“The captain was able to note a 5-6% speed increase. Now, this figure is really an important milestone for Shipshave; 5% it doesn’t appear to be much of a speed increase, but it translates into a good fuel saving.”

Main image credit: