ENVIRONMENT

HySHIP: inside Europe’s flagship hydrogen ship demonstrator project

Led by global shipping firm Wilhelmsen, the HySHIP project plans to build a zero-emission prototype vessel running on liquid green hydrogen, which it aims to promote as a viable maritime fuel option in Europe. Julian Turner gets the lowdown from Wilhelmsen VP special projects Per Brinchmann.

In 1806, French inventor Francois Isaac de Rivaz designed what is widely recognised as the world’s first ever internal combustion engine (ICE), which ran on a mixture of hydrogen and oxygen.

More than 200 years later, increasing numbers of climate campaigners, policymakers and industry experts agree that climate neutrality requires green or renewable hydrogen. It can be produced simply through the electrolysis of water or as a by-product from fossil fuel or renewable energy production without emitting CO2. It also carries three times the energy of petrol, diesel or jet fuel.

A recent study by the International Council on Clean Transportation (ICCT) found that 99% of the transpacific voyages made in 2015 could have been powered by hydrogen and fuel cells. More than half of those required only minor fuel capacity changes or just one additional port of call to refuel.

“Maritime is a large contributor of global greenhouse gas emissions and thus a priority sector to decarbonise,” said Bart Biebuyck, executive director at FCH2 JU, part of the EU’s Horizon 2020 innovation initiative. “Hydrogen and fuel cells have the potential to propel vessels in a zero-emission fashion and various ship types are starting to integrate them.”

In Europe, hydrogen is part of the EU’s long-term strategy to become carbon neutral by 2050. Fully electric and electric-hybrid ships already operate in several countries, including Norway, and now a new project aims to build a zero-emission prototype vessel running on liquid green hydrogen (LH2).

Wilhelmsen VP special projects Per Brinchmann. Credit: Wilhelmsen

Making LH2 a viable alternative maritime fuel

Funded by €8m from Horizon 2020, the 14-strong HySHIP consortium is led by Norwegian shipping operator Wilhelmsen, and includes Equinor and Strathclyde University in the UK. Together, they hope to make LH2 an attractive fuel option for ship propulsion throughout Europe.

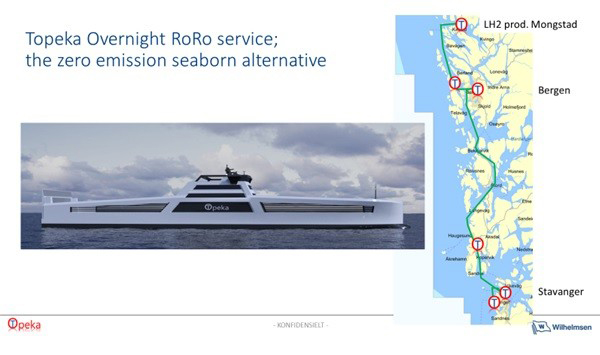

“The HySHIP project was established in January 2020, and at that time we were already developing our so-called ‘Topeka’ concept; a non-emission service to operate between the offshore supply bases on the Norwegian west coast,” explains Wilhelmsen VP special projects Per Brinchmann.

As well as ferrying customer cargo between Norwegian ports, the zero-emissions vessels will also deliver hydrogen sourced from clean energy to coastal fuel bunkers between Stavanger and Kristiansund, serving oil and gas platforms and an increasing number of wind farms.

The potential for emission reductions and by moving goods over to LH2-powered vessels is huge

The HySHIP partners hope that by doing so, they will create a comprehensive LH2 infrastructure and commercial ecosystem while removing 25,000 trucks from the roads every year.

“We will include hydrogen trailers to supply hydrogen from the production plant at Mongstad to filling stations, which we will establish on our NorSea offshore bases on the route,” says Brinchmann.

“Today, hundreds of trucks move goods between the Stavanger and Bergen areas on a daily basis. The vessels developed by HySHIP will carry road trailers as the main cargo. The potential for emission reductions and safety improvements by moving the goods over to LH2-powered ships is huge.”

The zero-emissions vessels will deliver hydrogen sourced from clean energy to coastal fuel bunkers between Stavanger and Kristiansund.

Inside the Topeka prototype vessel

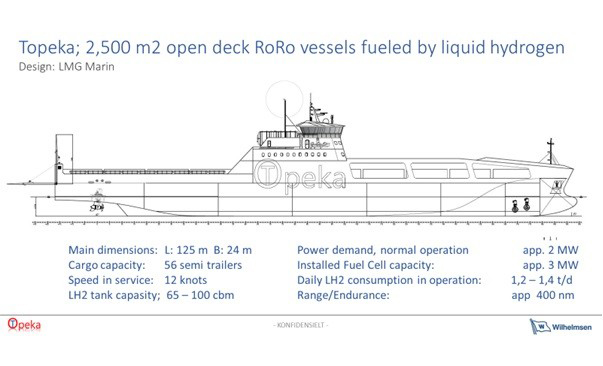

The prototype will run on a 1MWh battery pack and a specialised 3MW proton exchange membrane hydrogen fuel cell charged by power from the shore. By using batteries, the HySHIP team hopes to optimise the load and efficiency of the fuel cells. The vessels are expected to begin operations in January 2024.

“The hydrogen will be produced by electrolysis, fed by green electricity from the Norwegian national grid,” says Brinchmann. “For onboard use, LH2 is a very clean and easy-to-handle type of fuel. Hydrogen in combination with fuel cells is the only known energy system, besides nuclear, that we may call absolute emission-free. The only emission is vapour in the form of steam.”

Designed as an open-deck roll-on/roll-off (RoRo) vessel, the 2,500m2Topeka is capable of handling containers and trailers carrying both liquid and compressed hydrogen.

LH2 is a very clean and easy-to-handle type of fuel

The HySHIP project will also develop several ‘replicator’ LH2-powered vessels, including a smaller tanker barge of 0.5MW for use on inland waterways, a fast ferry and a 20MW deep-sea vessel.

“Stolt-Nielsen operates a fleet of inland waterway vessels that may cut their emissions significantly by shifting to hydrogen as European countries are now developing their hydrogen infrastructure,” says Brinchmann. “Norled is a leading Norwegian ferry operator with ambitions to shift to liquid hydrogen as a fuel for its fast ferries. Finally, Diana Shipping is a Greek owner with capesize bulkers and will investigate how liquid hydrogen may become a long-term option for deep-sea operations.”

The Topeka prototype will run on a 1MWh battery pack and a specialised 3MW hydrogen fuel cell charged by power from the shore.

Overcoming hurdles to hydrogen adoption

So far, so impressive. However, scaling up hydrogen production and use is fraught with challenges.

Hydrogen is liquefied by cooling it down to 20K (-252°C), which is a complex, energy-intensive process. Much of it is produced using fossil fuels, resulting in carbon emissions. It is difficult to store and experience with LH2 in a distributed energy system is lacking, as is the requisite infrastructure.

With no full-scale hydrogen-fuelled ships currently in operation, is Brinchmann confident that the HySHIP project can succeed in taking a first step towards scalable LH2-fuelled maritime operations?

The challenge so far has been the lack of infrastructure for hydrogen

“We believe the technology is mature enough to go to market,” he says. “There will be obstacles in scaling up, but these can be handled. The challenge so far has been the lack of infrastructure for hydrogen, which again is a consequence of low demand, which again is a result of lack of economic incentives and regulatory requirements to shift from polluting fuels.”

There are signs that this is changing. In 2018, the IMO agreed that emissions from global shipping should peak as soon as possible and then fall by at least 50% by 2050 compared with 2008 levels.

Implemented on 1 January 2020, Regulation 14.1.13 of Marpol Annex VI states that sulphur content of marine fuel used on board ships must be reduced from 3.5% mass by mass (‘m/m’) to 0.50% m/m for all vessels not fitted with exhaust gas cleaning systems (EGCS), or scrubbers. In parallel, SOx emissions are controlled in emission control areas to stop the use of fuel with a sulphur content of more than 0.1%.

The HySHIP project aims to remove 25,000 trucks from the roads every year.

From 1 March 2020, the Carriage Ban will prevent any ship not fitted with an EGCS from carrying marine fuel with a sulphur content over 0.50% m/m for use on board.

Two centuries after hydrogen played a key role in the world’s first ICE, this type of regulation – plus the fact that the maritime sector could soon be part of the EU’s carbon market and operators may be forced to buy pollution permits – could be just the kick-start the nascent LH2 industry needs to scale up.

“There is no chance to compete with traditional fuels such as marine gas oil, heavy fuel oil and liquefied natural gas without changes in the regulatory landscape,” says Brinchmann. “When CO2 emissions start costing significant amounts, or when emission requirements get much stricter, the industry will respond.”

All image credit: Wilhelmsen