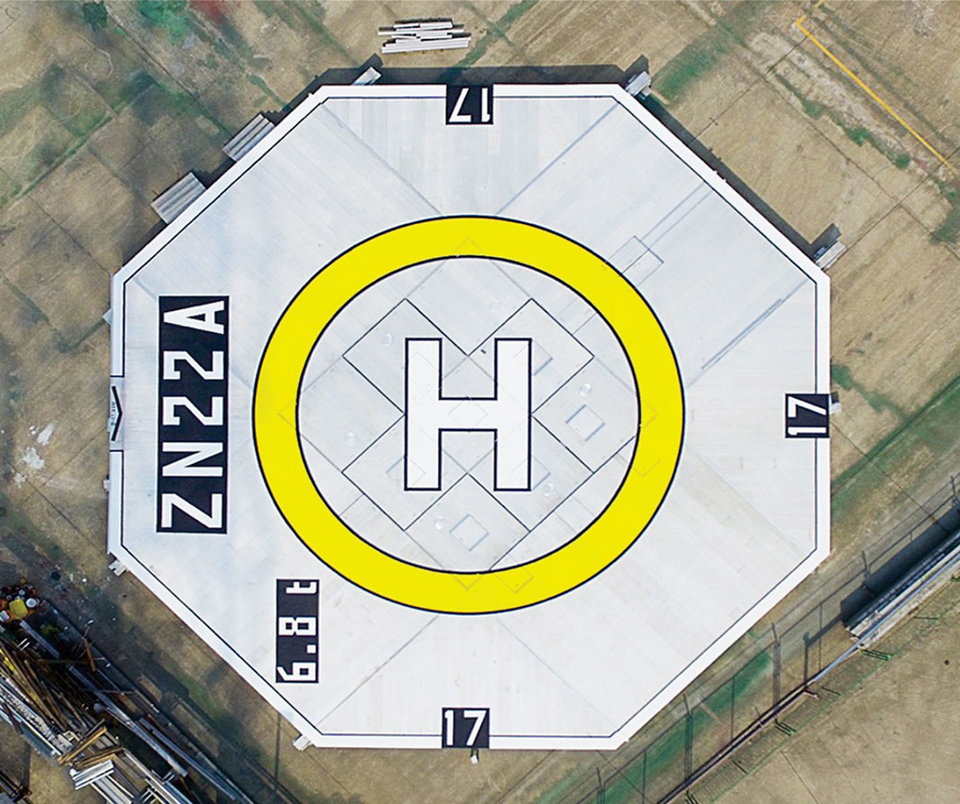

We currently provide over 50 units of heliport to offshore and connecting bases. We provide special marine type alloys in pre-fabricated modules, such as decking panels, T-bars, etc. We could provide standard and tailor made units and living cabins for offshore platforms. All kinds of fabrication enquiries will be considered from general CNC machining to FSW (Friction Stir Welding).

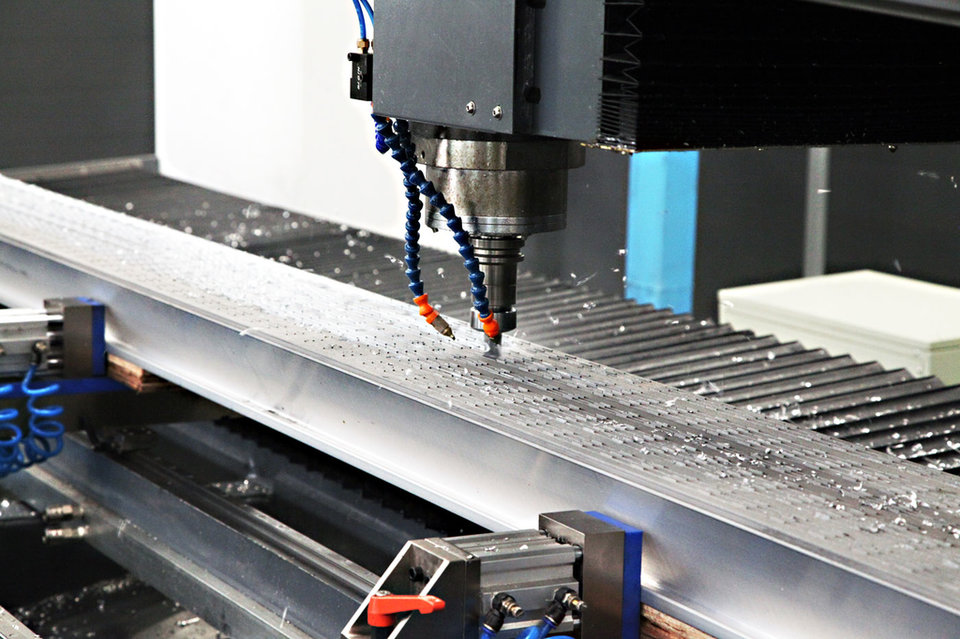

Press Metal International Technology is our fabrication base, granted DNV and ABS accreditations, the company has more than two hundred sets of precision machines, such as lathes, milling machines, presses, drilling machines, cutting machines, CNC machining centres, bending machines, presses, tapping machines and other equipment, which are used to process aluminium products with different specifications, angles, and precision requirements for the annual capacity of up to 60,000 metric tons. Combining the advantages of the upstream industry chain and collectivized operation management, Press Metal is fully able to meet customer demand for product diversification, stable and reliable product quality, and fast and efficient delivery.