About RWO Veolia

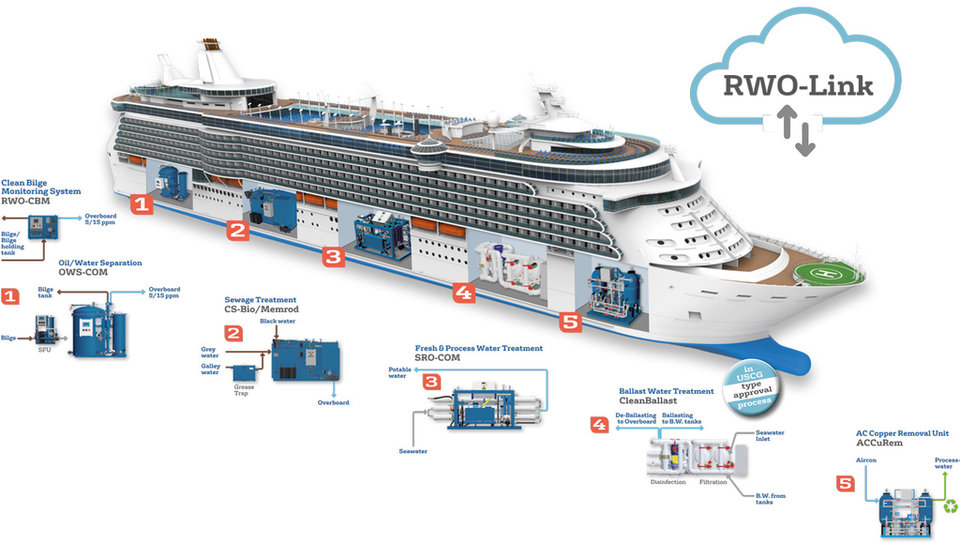

For more than 40 years the RWO experts develop, design, manufacture and service high-quality technologies for water treatment onboard ships and offshore installations, both for new installations or retrofitting. The product portfolio includes systems for oil water separation, waste water treatment, fresh and process water treatment. RWO benefits from an international network with more than 40 qualified sales/service stations, ensuring quick response and service times.

RWO is part of Veolia Water Technologies, a leading design and build company and a specialized provider of technological solutions in the areas of water and wastewater treatment.

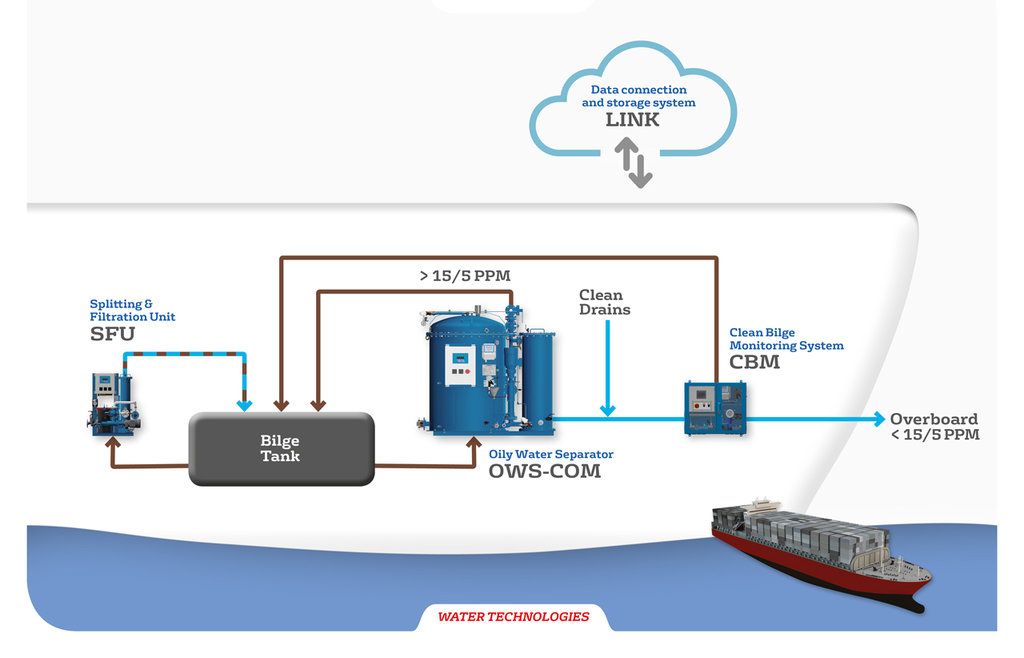

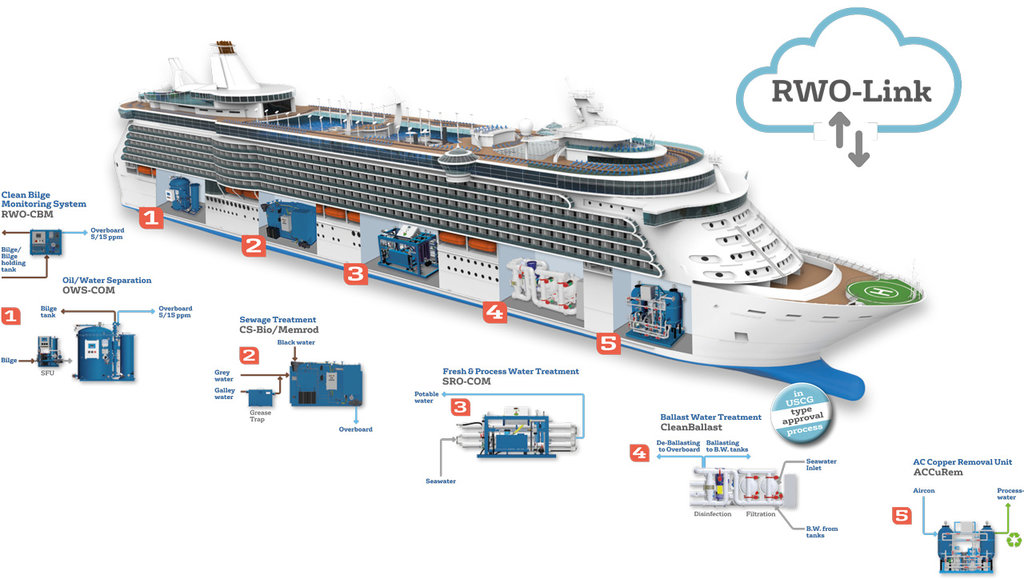

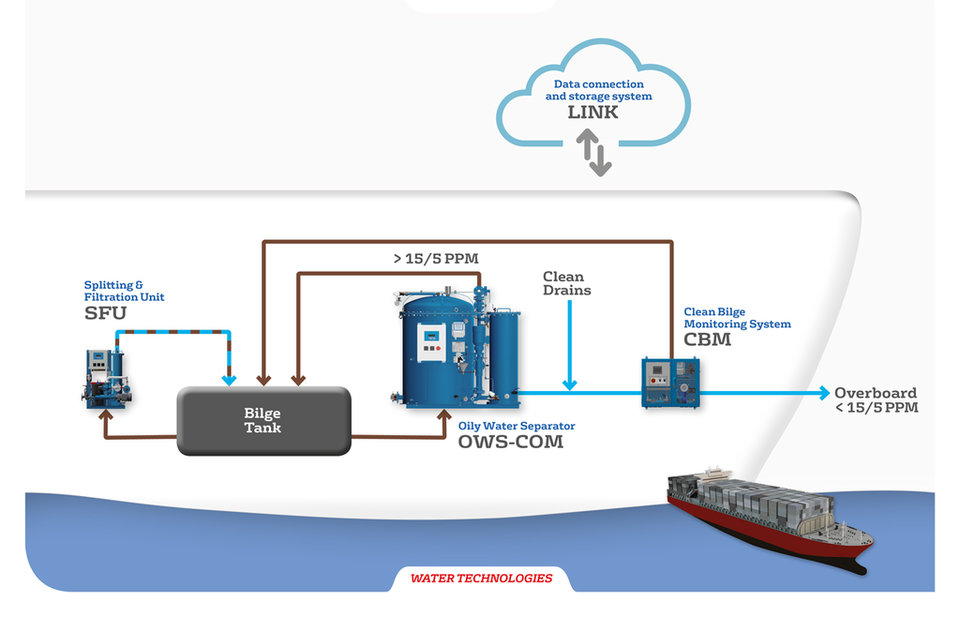

Bilge Water Management

RWO’s oily water seperator OWS-COM uses a combination of highly effective open porous coalescer with automatic backflushing, together with a second stage emulsion breaking oil and hydrocarbon polisher. The periodical backflushing keeps the coalescer surface clean and offers long lasting operation according to IMO Resolution MEPC.107(49). To extend the operating life of the demulsifier, an automatic bypass is fitted to the separating system. The oil content monitor periodically checks the water quality of the first stage separator. If below the set max. value, the demulsifier is bypassed. This results in lower operational cost and long product life. The RWO oily water separating system is equipped with a 15 ppm oil content alarm device, type tested and approved in accordance with IMO Resolution MEPC.107(49).

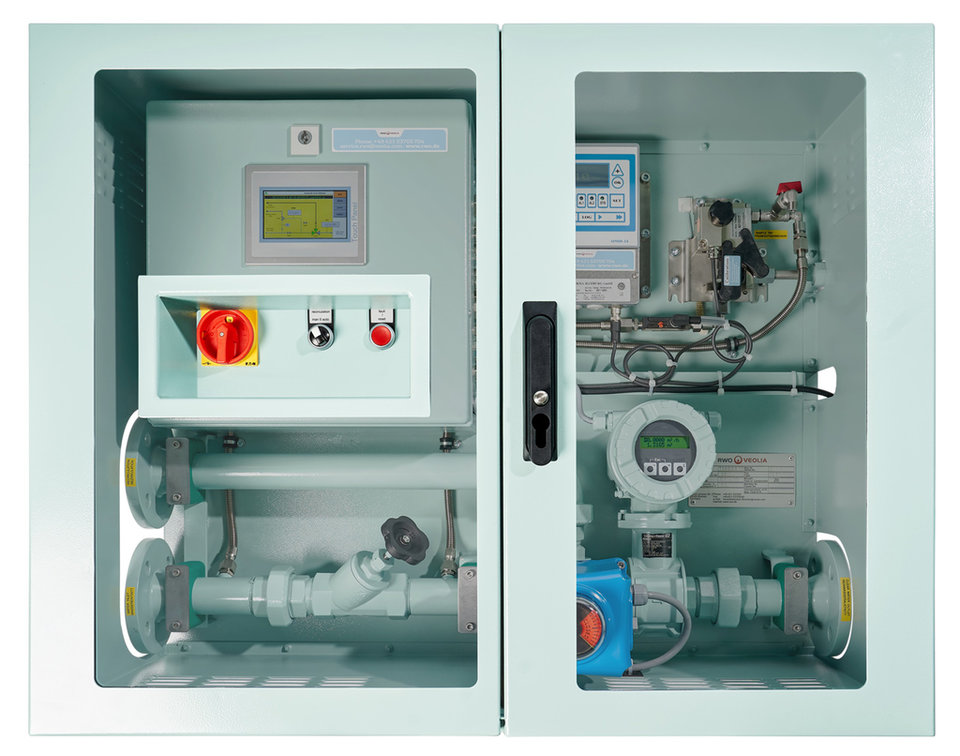

A range of additional products are available for bilge water treatment, such as a bilge economizer to monitor the clean drains and reduce the load for the oily water separator, a splitting and filtration unit to pretreat the bilge water and a clean bilge monitoring system, CBM-Link. CBM-Link is compromised of two systems working together seamlessly: CBM acts as the final control mechanism before bilge water is discharged The system independently monitors whether, as prescribed by IMO Resolution MEPC 107 (49) for particularly sensitive sea areas (PSSA), maximum oil content of 0, 5 or 15 ppm in the water being discharged is complied with and automatically transfers it either directly overboard or to the bilge water tank for further treatment. LINK is a software system which provides detailed information about the operation of the system as well as the composition of the bilge water. The information can be visualised in real time, enabling timely adjustment of system modes. Connected to the ship's communication system, the system is able to access GPS coordinates. Based on the data collected during the test phase, future features will be developed to further optimise operation of the system.

Fresh Water Treatment

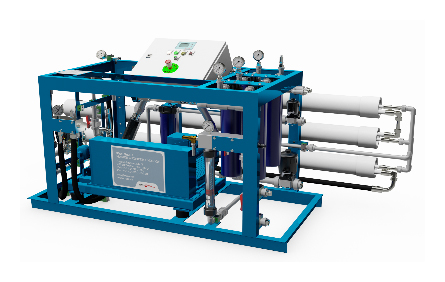

RWO’s SRO-COM is a standardized seawater desalination plant for service onboard ships. Seawater reverse osmosis plants are an advantageous solution whenever desalinated water for drinking, utility and process applications is needed. The technology is simple, the operation easy and only limited maintenance is required. RWO has now completed the re-design of smaller systems, and offers this standardized »off-the-shelf« unit for capacities up to 60 m³/day. This desalination plant has a stable permeate flow over the complete temperature range from 1°C to 35°C. The SRO units come with a built-in concentrate displacement device that will extend the membrane operation cycle. The newly developed SRO-COM seawater reverse osmosis plants from RWO offers state-of-the art technology by using low energy membranes. Compared to conventional systems, they produce the same permeate rate at a considerably lower operating pressure, resulting in lower investment and lower energy costs. The heart of the plant is the integrated electronic control device, with a user friendly digital display. The graphic on the display shows the temperature, conductivity, operating pressure and operating hours. All failure recordings including the alarm and warnings can be checked through the menu feature.

Sewage Water Treatment

RWO offers two solutions for sewage water treatment.

CleanSewage Bio is designed to minimize the attention with sewage treatment to the lowest level possible. The accessibility from one side allows ship designers to plan space in the engine room on a whole new level. Operators and crew are pleased with a hygienic no-touch-cleaning system, an intuitive status control allows checking at a glance, whether the system is running or intervention is necessary. Thereby CleanSewage Bio works with a proven biological treatment technology compartmentalized in 3 process steps that ensures the highest water quality according to MEPC.227(64).

Shortly, RWO will launch a new sewage water treatment for cruise ships. The system, CS-MBR, benefits from extremely durable membranes that are back flushable, long lasting and easy to remove without entering the reactor. The operation interface is designed with the upmost user friendliness and easy operation in mind. A system for remote support and data analysis is also available to allow for predictive maintenance.

Total intelligent water management

In the context of total intelligent water management RWO also offers systems for process water treatment and can offer large bespoke systems to meet the every customer’s individual needs. We can also equip Offshore platforms with bespoke and off the shelf water treatment systems.

Contact details

RWO Veolia Water Technologies Deutschland GmbH

2. OG / 3rd floor

Gerold-Janssen-Str. 2

28359 Bremen, Germany

Phone: +49 421 53705-0

Web: www.rwo.de