Why Heavy Fuel Oil (HFO) Bunker tank inside insulation?

Heating bunker heavy fuel oil (HFO) with properly isolated bunker tanks insulation reduces emissions, costs and other drawbacks considerably.

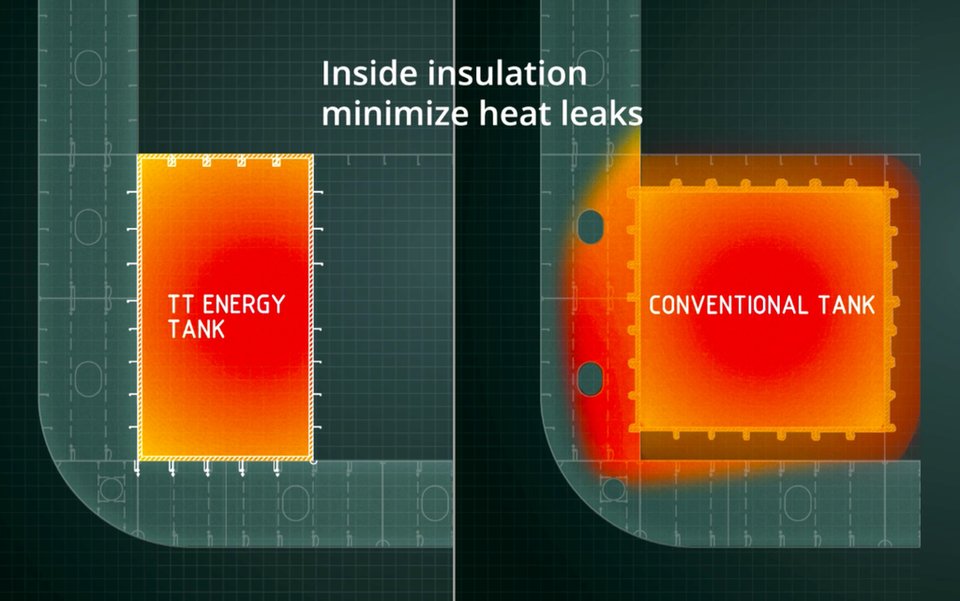

There are several drawbacks by using external insulation on bunker tanks; external insulation will never provide a completely sealed system, there will be gaps, not possible to insulate since the tanks are structurally directly connected to the hull. This causes thermal spots, the leak which transfers considerable amounts of heat to areas adjacent to the heavy fuel oil bunkering, TT Energy Tank insulation is the only inside insulation system that can stop all heavy fuel oil bunker tank thermal leak points in a vessel.

External bunker tank insulation is often as good as leaving a thermos can open - it does not do a very good job in keeping the inside hot and the surrounding cool. Even seemingly small thermal leak areas reduce the efficiency of the insulation considerably. The only way to insulate a bunker tank properly in an efficient and cost-effective way, is to insulate it from the inside. TT Energy Tank is the first bunker tank inside insulation on the market, and the only bunker tank insulation that really does what it says on the thin. TT EnergyTank insulation method and materials are protected with international patents. TT EnergyTank heavy fuel oil bunker tank insulation is cost effective, quick to install and has a very short payback time.

A Proven Patented HFO Bunker Tank Innovation

Insulation on the inner side of the tank reduces energy consumption by up to 90%

By placing the insulation on the inner side of the Heavy Fuel Oil (HFO) tank, the TTEnergyTank insulation method can save up to 90% of the heating costs. This is because this method eliminates heat transfer bridges, which make normal insulation methods, where insulation is on the outside of tanks, inefficient – especially on ships where integrated tanks are used. Depending on the vessel’s design, its HFO system and its operation profile, the total fuel saving could be even up to 90% of the total tank heating consumption. The emissions will also be similarly reduced. The gas oil consumption in ports will be significantly reduced, in particular when tank heating can be turned off.

Effective, reliable and tested system

The insulation material and fastening system have been tested for oil products up to +200°C and field tested in HFO bunker tanks onboard ships. The insulation is extremely effective, with the thermal coefficient of the material calculated to be around 0,05 W/mK. This value is particularly impressive as it can be applied to the whole surface area of the tank, since this method eliminates cold bridges. TTEnergyTankHFO Bunker Tank heat insulation is reliable and has been used successfully since 2009 in different types of vessels working all over the world.

Heating slings mounted on top of the insulation

The tanks heating slings can be mounted on top of the insulation without being in contact with the tank bottom. This will increase heavily the effectiveness of the slings transfer of heat in to the oil without any thermal heat bridges. This increases the effectiveness of the tank heating tremendously.

Reduced energy consumption for booster unit and separator-heaters

A bunker insulated with TT EnergyTank can be kept at a higher temperature without heat losses; as a result the heating system, which heats up the HFO bunker before pumping the fuel into the engine also has to work less.

Ecological issues and harmless to structure and machineries

TT EnergyTanknot only saves fuel it is also an ecologic solution reducing emissions in use. The patented thermo treatedinsulation material is 100% ecological and uses organic raw material. Changes in heat or moisture have almost no effect on the dimension of the material and will therefore not affect the tank structure. It can easily be recycled and it is harmless to machinery and pumps, and to the environment.

Engine room temperature reduced

When the ships bunker tanks are insulated with TTEnergyTank the temperature in the engine room becomes easier to control.

Clean steel surfaces reduce fire risk

Surface mounted insulation material easily becomes soiled by a build-up of oil, which is unsightly and increases fire risk. With inside insulation installed in the tanks, the engine room will have clean steel surfaces instead and the fire risk is reduced.

Reduced corrosion

With the TTEnergyTank system installed, tank surface temperatures will be lower. This means that ballast tanks in contact with bunker tanks will not be affected by corrosion in the same way as before.

Long lifetime without maintenance

The lifetime of the insulation material is estimated to be longer than the normal lifetime of a vessel and no maintenance is needed. The insulation can, if necessary, be easily removed for repair work or inspections, and reinstalled.

Acacia Noir, Cargo tank no 5 SB, Heating slings mounted

No corrosion

Fast, easy installation – even on existing ships

TTEnergyTank isolation for bunker tanks is easily installed in just a few days, on both existing ships and new builds. All materials can be inserted through the manholes in the tank, with no need to cut access holes. The only requirement is that the tanks need to be gas-free before installation. The insulation material is fastened to the ship’s tanks using an innovative quick fastening system, reducing the installation time to just a few days.

Reference list:

Ship name:

Sydgaard

Alp Striker

Alp Defender

Alp Sweeper

Alp Keeper

Celibrity Infinity

Celibrity Summit

Celibrity Millenium

Celibrity Constellation

Acacia Noir

Magbit 9

Type of Ship

Dry Cargo

AHST

AHST

AHST

AHST

Cruise Ship

Cruise Ship

Cruise Ship

Cruise Ship

Bitumen Tanker

Bitumen Carrier

Owner/Manager

Bore Shipping Ltd

ALP Maritime Services

ALP Maritime Services

ALP Maritime Services

ALP Maritime Services

RCCL

RCCL

RCCL

RCCL

Wisby Tankers Ltd

Puma Energy

Installation

8/2009

8/2015

6/2016

8/2016

3/2017

10/2015

1/2016

3/2016

4/2016

4/2016

04/2019

Type of installation

Bunker, Retrofit

Bunker, Newbuilding

Bunker, Newbuilding

Bunker, Newbuilding

Bunker, Newbuilding

Bunker, Retrofit

Bunker, Retrofit

Bunker, Retrofit

Bunker, Retrofit

Cargo tanks, Retrofit

Cargo Tank Retrofit

TT EnergyTanks, Background: In Pursuit of the IDEA

As the saying goes need is the mother of all invention, TT Energy is no exception to that. Tom Sommardal the owner and founder of Northern Tanker Company, by profession he is Naval Architect and has been associated with shipping and Marine industry for almost three decades, during his tenure while working onboard ships, the energy efficiency of fuel used, was bothering him, in one such instance he observed that the asphalt which is carried on board of the ship had to be maintained at 200 degrees and the space between the Cargo tank and the outer shelf used to be hot as Finnish sauna, this made him to think how this energy can be harnessed which was being wasted.

Hence, the idea was born, why not insulate the cargo tank from the inside, similar to Wooden Finnish Sauna, Now the challenge was to take this idea to the market by patenting the same, The strategy was to directly market to the shipping industry, but the bitumen market was niche and market was small, even though the idea was good, the returns were not good, since in the changes in the shipping industry are hard to come by.

Now if we have to make a business of the innovation, your product should reach out to many customers in other words, we needed more paying customers, hence the thought of why only Bitumen carriers why not ships using HFO, since almost all the ships in the world use HFO and have HFO fuel tanks.

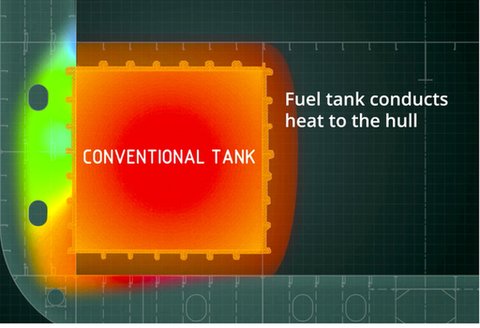

The problem of huge heat leakage due to bad insulated HFO fuel tanks on ships, led to higher fuel consumption and corrosion problems, in the below Figures depict how the conventional fuel tank conducts heat to the hull of the ships, whereas TT energy tanks when insulated from inside eliminate the heat leakage to the hull and eliminated the cofferdams around the fuel tanks which resulted in more cargo space.

Source: TTEnergyTanks, Northern Tanker Company

Source: TTEnergyTanks, Northern Tanker Company

Having the insulation from inside the Heavy Fuel Oil Bunker tank brought in many benefits in terms of reducing emissions and also in terms of bunker heating cost saving up to 90%.

Also due to less heat in the machine rooms, cabins and spaces located near the bunker tanks provided increased comfort. and made spaces that otherwise were unusable due to excessive heat useful, also it reduces the corrosion.

Also, the added benefit is having the clean steel surfaces in the Engine rooms, due to the fact the insulation is been eliminated from the outside of the fuel tank, which reduces the fire hazard.

Contact us

Northern Tanker Company Oy

Katajanokanlaituri 5

00160 Helsinki

Finland

Email: tom@lngtainer.com

Email: info@lngtainer.com

Webpage: www.TTEnergyTank.com

Tel: +358 400 530 595