Company Insight

Sponsored by Alnor

Alnor’s Pre-insulated Ducts And Fittings Spiral® Marine System

Shipbuilding is a highly challenging process especially in terms of installation of ventilation systems and air conditioning.

Main image credit:

Shipbuilding is a highly challenging process especially in terms of installation of ventilation systems and air conditioning. The ventilation system must be resistant to changing weather conditions, high humidity and salinity, while being failure-free and easy in maintenance.

Reliability and maintenance are key aspects of shipbuilding since in the case of some equipment failure at land construction You can easily seek assistance, however, at sea it is virtually impossible. Employees of vessels must be able to quickly and efficiently repair a failure, otherwise compromised can be a health or life of the ship crew.

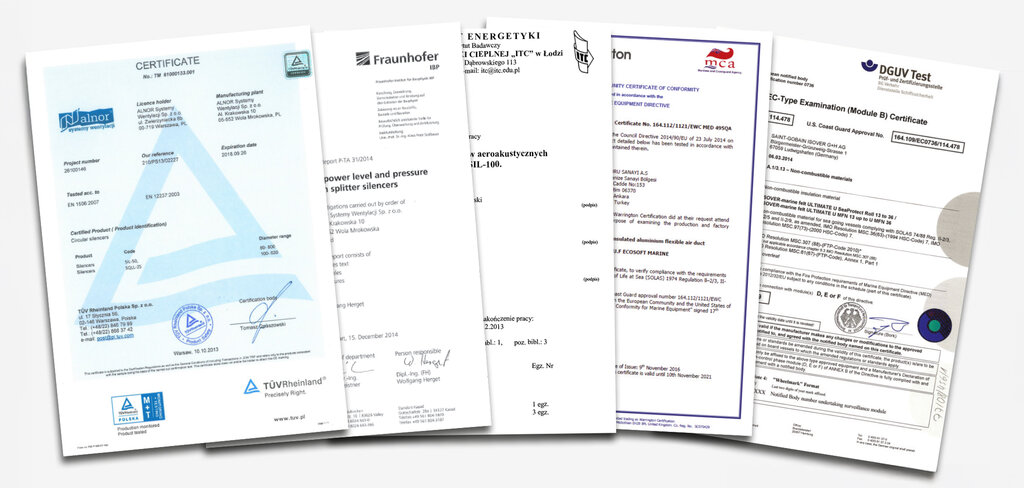

Alnor Pre-insultaed products quality is confirmed with the most important certificates:

- SPIRAL® system silencers made of galvanised sheet metal have the hygiene certificate. The rectangular silencers have the hygiene certificates:

a) for those made of galvanised sheet metal

b) for those made of stainless steel sheet metal - SPIRAL® system round ducts and fittings have the hygiene certificates: a) for those made of aluminium sheet b) for those made of galvanised or stainless steel sheet

- TÜV Rheinland Monitoring + Testing - Round ventilation silencers

- RISE Technical Approval no. 0103/07 - Distribution of air demand for air tightness class D according to EN 12237.

- Fraunhofer-Institut für Bauphysik IBP - Insertion loss, sound power level and pressure loss measurements on splitter silencers.

- Selected SPIRAL® system acoustic dampers were tested by the Institute of Power Engineering - Research Institute - “ITC” Heat Technology Department in Łódź. Echo chamber measurement method was used, in accordance with the standard:

a) PN-EN ISO 7235:2009 “Acoustics. Laboratory measurement procedures for ducted silencers and air-terminal units. Insertion loss, flow noise and total pressure loss”.

b) PN-EN ISO 3741:2010 “Acoustics - Determination Of Sound Power Levels Of Noise Sources Using Sound Pressure - Precision Methods For Reverberation Rooms”.Ventilation ducts and fittings with 16 mm this wool insulation (possible: galvanized/aluminium 1.4301/1.4404)

Our permanent offer includes:

- Elements with 10mm thick insulation (wool and air)

- IZOL Safe – with a seal on the inside and outside of the fittings’ shell

- Galavanized round elements of tightness class D (aluminum and acid-resistant)

- Aluminium ventilation ducts and fittings

- Acid-resistant ventilation ducts and fittings 1.4301/1.4404

- Products with 25mm thick insulation – marine wool

- Silencers, dampers, grills, diffusers and many more are also available in Revit - BIM libraries, MaciCAD, Ventpack programs.

We also produce ventilation ducts and fittings form the fresh air extraction and distribution system for industrial, detached houses and blocks of flats.

The ventilation tubing comprises spiral tubes, bends, T-pieces, reducers, connectors, plugs and takeoffs– pressed and segmented with diameters from 80 to 1600 mm.

A standard ventilation system is made of galvanised sheet metal. In a case when the fittings are equipped with a gasket they comply with the sealing class D in accordance with the PN-EN 12237:2005 standard.

Alnor circular ducts and ductwork elements are manufactured according to Swedish Technical Approval no. 0103/07 issued by SP Certifiering.

Ventilation elements made of stainless steel or aluminium sheet can be used in atypical places with increased humidity or in places where ventilation tubes come in contact with chemical agents

The company started its business activity in the year 1994 as the manufacturer of spiral ducts. It has been constantly developing its product range for 30 years, providing effective ventilation solutions to over 80 countries.

Right now Alnor is one of the most rapidly developing companies in the industry. We use about 10 000 tones of sheet per year. The total area of our warehouse halls is over 10 000 m2 owing to which we shorten the delivery time of our products to the maximum.

Contact information

ALNOR Systemy Wentylacji Sp. z o.o.

Email: export@alnor.com.pl

Web: www.ventilation-alnor.co.uk