Q&A | Shipbuilding

RAMSSES:

a new era of lightweight materials in shipbuilding

While advanced composites are common in aviation and car building, most ships are still made of heavy steel, something the EU-funded project RAMSSES is keen to change. The project is collaborating with industrial and research partners on hulls, superstructures, decks and cabins, as well as rudders and propellers. Frances Marcellin finds out more from CMT research and development engineer Matthias Krause.

On 1 January 2020,

in an attempt to reduce greenhouse gas emissions, the shipping industry started navigating one of the biggest changes it has ever seen: adhering to a new sulphur level in fuel that is no more than 0.50% m/m, in line with the International Maritime Organization (IMO’s) MARPOL 2020 agreement.

According to the IMO, 2.5% of global greenhouse gas emissions are caused by the global shipping industry, and its Third Greenhouse Gas Study states that shipping emissions could grow by between 50% and 250% by 2050.

While compliance means using exhaust gas cleaning systems (EGCS) or alternative fuels, using composites and more innovative, lightweight materials will also bring environmental benefits by reducing energy and fuel costs.

This is what the EU-funded RAMSSES project aims to achieve. Having launched in June 2017 and running until May 2021, it is working with 36 different companies who have been developing 13 demonstrators – applying innovative material solutions like composites or advanced steel for future commercialisation.

As the Centre of Maritime Technologies is the technical coordinator for RAMSSES, Frances Marcellin spoke to Matthias Krause, a Research and Development Engineer at CMT, whose role is to initiate new research and innovation projects.

Frances Marcellin:

What is the role of the Centre of Maritime Technologies (CMT) on the RAMSSES project?

Matthias Krause: The technical coordination, as well as the coordination of all the publications, is taken care of by CMT. The financial and administrative co-ordinator is Cetena, an Italian naval research and consultancy agency.

FM: Why do companies hope to achieve through involvement with RAMSSES?

MK: The 13 different demonstrators are focused on particular products being realised at the end of the project. The project partners want to develop something they can apply to the ships they are producing, like a piece of the structure made of composite materials, or new hollow propeller blades produced by a 3D-printed metallic structure.

The various tasks in the project need to be coordinated by someone, so we need to ensure that everybody is meeting their deadlines, not running out of budget and take care of the tests that are needed to show everything is safe because we’re also dealing with combustible materials.

It is both about the management of technical risk and management risk, and, of course, we have experts for the technical risk. We have experts, research institutes and certified testing laboratories, who are really in-depth experts in, for instance, fire issues. They are carrying out tests in order to demonstrate that everything that we’re doing is ready for approval and can go afloat at the end of the project.

Naval Group is developing the world’s first hollow propeller blade created using the Wire Arc Additive Manufacturing (WAAM) process. Image: CMT

FM: How were these 13 demonstrators chosen?

MK: We had an internal call for ideas and there was interest from many companies, so we had to make a choice. Some of the ideas were a bit premature. What the European Commission was asking for in the call for proposals was innovation action.

FM: How do you know if the ideas are developed enough and at the right stage?

MK: Are you familiar with the term TRL? TRL means ‘Technology Readiness Level’. It is a standardised way to indicate the maturity level of a new technology.

Maybe some new physical phenomenon has just been discovered and you don’t know how you can apply it to a product, that would be TRL 1. On the other hand, you have TRL 9, which means you have conducted all the tests, identified how to use the technology in a product, shown it meets all the requirements and it is safe to be produced in an efficient way.

The call from Brussels was asking for ideas with a comparatively high TRL, so only dealing with innovations which are close to application.

FM: How else can the maritime industry benefit from RAMSSES?

MK: What we want to achieve is to improve the general situation of anybody who is interested in introducing new materials to shipbuilding, because very strict rules exist when designing a new ship made of steel. This is the traditional way to design ships. When it comes to new materials, it becomes complicated, because then you have to demonstrate what have in mind with new materials that are not explicitly covered in the rules.

All 13 demonstrators developed within the RAMSSES project aim to be commercialised and hence will be thoroughly assessed in the course of the project to ensure acceptance from customers as well as the classification societies.

Damen Shipyard is developing a custom-made hull for an 80m offshore vessel (left) and thick and unique oblique layer laminates by Infracore (right). Image: CMT

FM: What are some of the complications regarding the use of new materials?

MK: Those new ideas must offer the equivalent safety level compared to conventional steel structures and this is where the discussions with the classification society begin. You have to show, by means of laboratory tests, that the materials you’re dealing with, and the design you’re going to apply it to, are safe. It involves lots of negotiations, time and of course plenty of money.

FM: Can this process be improved?

MK: We do see the opportunity to modernise this approval process and make it more innovation-friendly. Based on this idea, we have been developing within the RAMSSES project a “smart track to approval”. It would be a more structured way of showing that a product meets these safety criteria which we propose to the regulatory bodies, especially the IMO.

FM: Can you tell me more about what these 13 demonstrators are working on?

MK: We have three types of demonstrators in the project. The first is the components and equipment. So you might imagine a company that is producing elements of ships, it could be a supplier who produces rudders or propellers, or a supplier that produces modular walls, which can be used, for instance, in cruise ships, in the corridors [or] in the passenger cabins.

The second one is shipyards: small shipyards and large shipyards. The small ones build work or leisure boats, and the big ones build cruise liners. We have all the big shipyards in Europe in the consortium that are building cruise liners: Meyer Werft in Germany, Meyer Turku in Finland, Chantiers d’Atlantique in France and Fincantieri in Italy. They have to ensure that whatever they do using new materials is compatible with the conventional materials they are already using.

The third group of demonstrators is dealing with steel, but there are advanced types of steel on the market like high tensile steel which offer better properties – you can use, let’s say, 5mm steel sheets instead of 7mm steel sheets. These are the three groups of demonstrators we have.

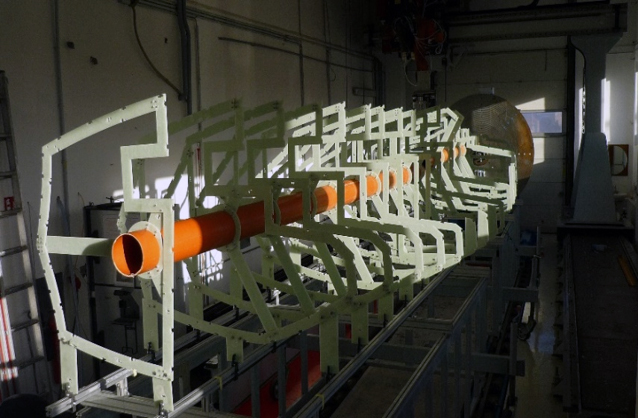

Demonstrator of ultra-low weight modular system using a highly automatic winding manufacturing process by BaltiCo GmbH. Image: CMT

FM: What advantages do composite elements have over steel or more traditional materials?

MK: You have fewer problems with corrosion obviously. If you think about new materials you might shy away from them because you are an expert in steel, but you still have to improve. The Green Deal and climate change challenges are very present in Europe nowadays, everybody is talking about new propulsion systems for ships, but the weight-saving aspect is very prominent in public discussions. I would like to make people aware of this, that this is also a good approach which should be used to reduce greenhouse gas emissions (GHG).

CMT's Matthias Krause. Image: CMT