IMO 2020 Implementation and Fuel Oil Quality Management

One year after the implementation of IMO 2020 regulation, the required switch to compliant low-sulphur fuel oil with sulphur content not exceeding 0.5% has so far raised a number of problematic and challenging issues for global shipping industry. Compatibility between fuels, stability, catalyst fines, flash point, pour point are among key concerns with regard to quality management of low-sulphur blend fuel oils. The occurring challenges are not new and well-known with respect to traditional heavy fuel oil, but close routine monitoring of the engine system before changeover to LSFO and back and regular verification of critical fuel oil parameters is essential to identify possible off-specification issues at the right time. Trend monitoring is also crucial to gather valuable experience with the new fuel batch to estimate overall engine system operation and separator performance.

Martechnic® considers quality management of the increased varieties of fuel blends accepted as LSFO directly on site as a priority and offers portable test equipment for direct on-board measurement and assessment.

Importance of Regular Fuel Oil Monitoring on Board

An initial low-sulphur fuel oil quality check is essential before using it for the engine system in order to reveal possible impaired properties of fuel oil and to make any necessary adjustments to ensure continuous and smooth engine operation. Regular application of portable measuring devices and test kits directly on board is easy and quick and enables engineers and users to conduct trend analysis to track any deviations from standard parameters.

Martechnic® recommends to use LSFO condition monitoring techniques and to test LSFO fuel blends before the new oil types enter the engine system. This will help to get early warning of possible engine failure looming ahead and so to avoid damages and uncontrolled down times.

Low-Sulphur Fuel Oil: Compatibility and Stability Concerns

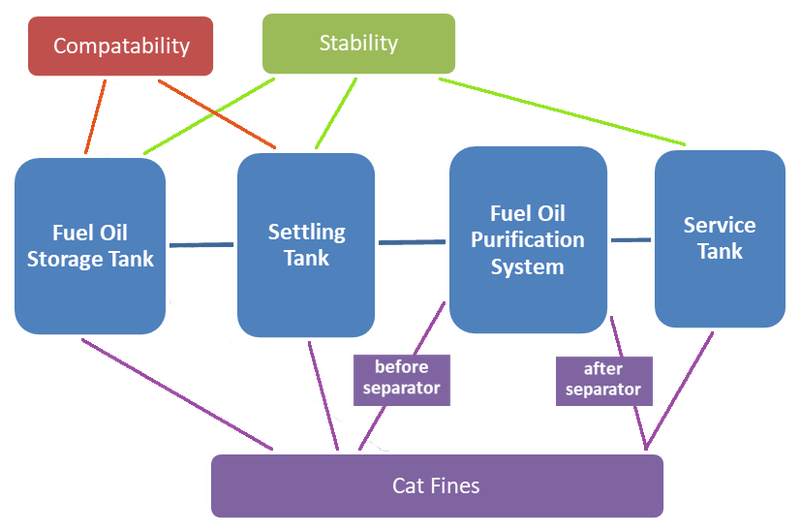

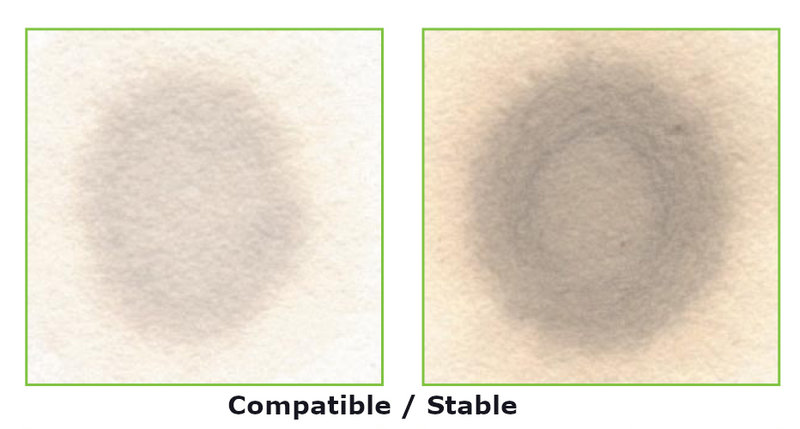

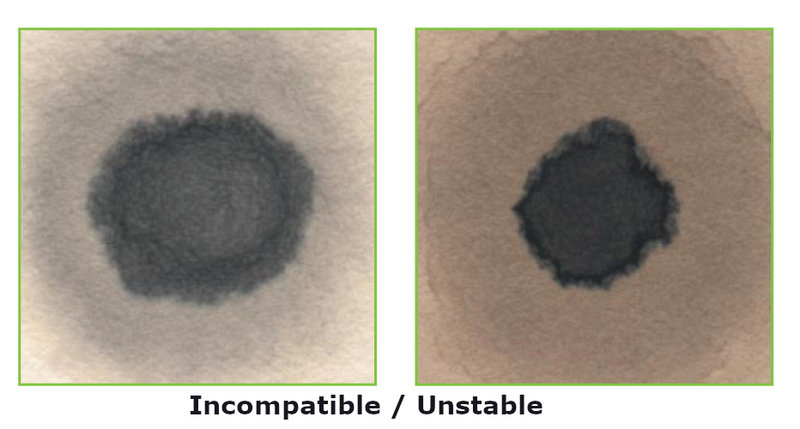

International existing standards and regulations provide general guidelines to avoid comingling whenever possible of bunker fuels from different sources on board a vessel due to potential compatibility problems that could result in sludge formation. These recommendations are especially critical with regard to a variety of low-sulphur fuel oil types currently available on the global market. New LSFO fuel blends have different compositional structures, i.e. aromatic or paraffinic rich fuel oils, formulated during various methods of refining and blending processes. It is important to always store different batches in separate fuel oil storage tanks and check on their compatibility prior to proceeding with fuel changeover (mixing new LSFO with leftover fuel) in fuel oil pipelines, settling and then service tanks. Quick and easy compatibility test with portable test kit “COMPA DENS CHECK” at bunker time helps to directly determine whether comingling can be done or should be avoided.

Another parameter of LSFO that requires regular verification is stability. Due to long periods of storage in a tank after bunkering and before actual use or thermal stresses, asphaltenes which are present in fuel oil in various concentrations can precipitate because of the low aromaticity or solvent capacity and form sludge deposit. This problem is especially relevant with regard to LSFO containing mainly paraffinic blends. Preventive fuel oil quality monitoring helps to avoid the risk of sludge formations and blockage of filters, separators and pipes of the engine system.

Cat Fines: Managing Low-Sulphur Fuel Oil Quality on Board

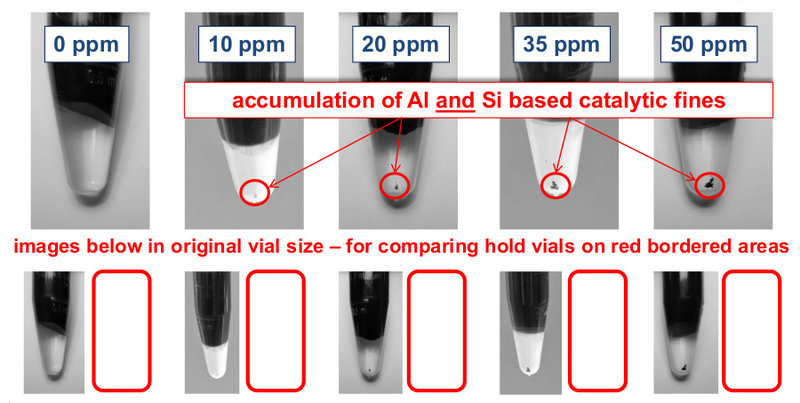

Cat fines (Al and Si compounds) are hard abrasive particles that remain in fuel oil as a by-product resulting from the catalytic cracking technology used in the intensive refining and blending process to reduce the sulphur content. Accordingly low-sulphur fuel oil tends to contain increased amounts of cat fines in comparison with conventional heavy fuel oil. When cat fines are present in big quantities in LSFO or of a large size, they can substantially damage the components of the engine system such as fuel pumps, fuel injection valves, cylinder liners and piston rings.

Transitioning to LSFO as a principal bunker fuel in order to reduce emissions, the issue of cat fines can be very challenging for the global shipping industry if not handled properly before the fuel oil injects into the engine system. The LSFO to be used for engine operation should always be placed separately in a storage tank and a representative sample of fuel oil needs to be tested on board a vessel in order to evaluate cat fines concentration.

LSFO is transferred to the settling tank and then via the fuel oil treatment system to the service tank. Fuel oil separators play a key role in further purification and reduction of cat fines before LSFO reaches the engine system. Managing LSFO quality and checking cat fines concentration before and after purification in separators is a crucial part of pre-consumption LSFO onboard analysis. This “double-check” strategy not only helps to determine discrepancies in initial LSFO quality delivered on board, but also to regularly monitor cat fines concentration in settling and service tanks and to estimate fuel separator performance.

Martechnic® offers portable test kit “MT CAT FINES CHECK” for regular on-site visual quantification of cat fines concentration in fuel oil.