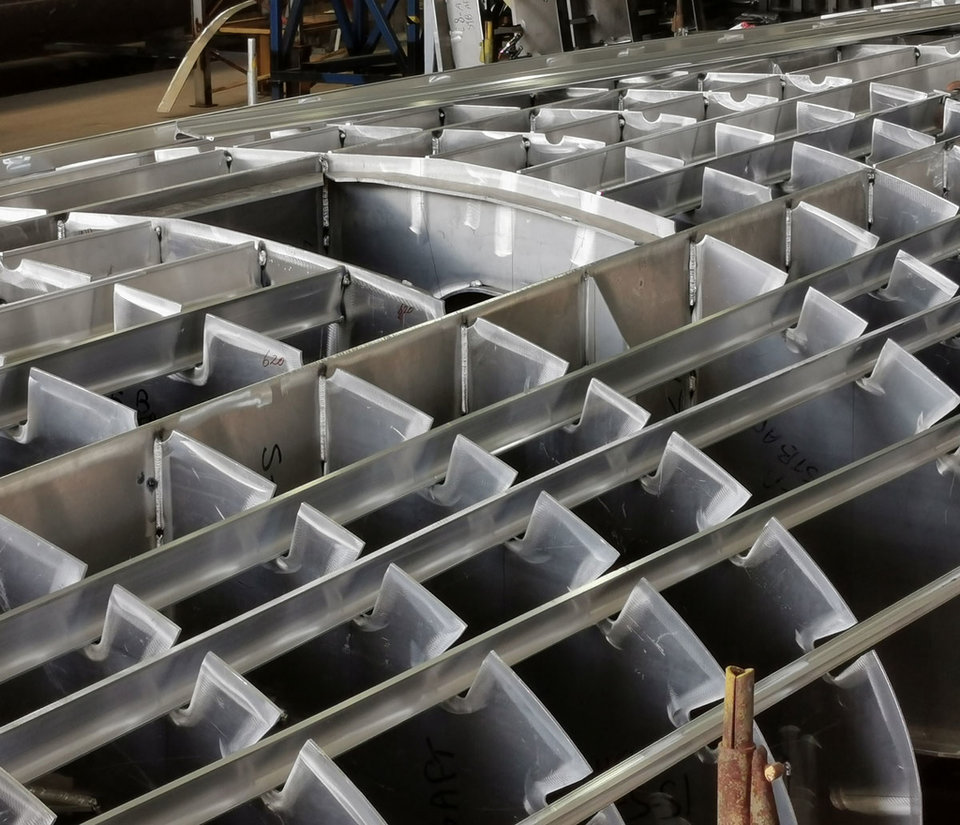

Focus on production and sales of aluminium profiles and parts, including marine products like ladder, porthole, mast, deck, plank, truss, container structure parts, helideck, etc.

Certified by Classification Society Certifications of CCS (China), ABS (America), DNV (Norway), BV (France), and NK (Japan).

Capable of development and production capability for 5xxx, 6xxx, 7xxx series aluminium.

Certified as National Hi-tech Enterprise, China Accreditation Laboratory & others recognition.

Complete production chain with billet casting, extrusion, surface finishing & advanced fabrication facilities.

Equipped with 7000T UBE extrusion press that able to produce complex-structure profiles.

The general annual extrusion capacity can reach 120K Tons.

The fabrication lines capable for various watercraft parts fabrication that serving customer's needs.

Targeted at watercraft, we breakthrough the previous process & develop the better extrusion process for 5383 alloy by technical optimization in alloy, extrusion, die, and heat treatment. It is not limited by the property of high strength, corrosion resistance, and weld ability, but also extrudability to different profile forms as customers' design desire. This is breaking the previous technology limit of profile shaping by cold work, then creating new ideas for light-weight watercraft designs which widely applicable for the use on medium to high end ships and marine platforms.