Company Insight

The future of hull cleaning

Demand for innovative and green technology is on the rise within the international maritime community. Stricter regulations aimed at controlling the harmful effects of foreign marine species carried beneath the surface on vessel hulls, the need to reduce CO2 GHG emissions and the harmful environmental impact of heavy metals in paints are being reviewed and gradually taken on board by ports and governments around the world.

SPC Cone Fender System | Ferry Terminal | Sweden

Demand for innovative and green technology is on the rise within the international maritime community. Stricter regulations aimed at controlling the harmful effects of foreign marine species carried beneath the surface on vessel hulls, the need to reduce CO2 GHG emissions and the harmful environmental impact of heavy metals in paints are being reviewed and gradually taken on board by ports and governments around the world.

Caption

Recognising the risk

Hull fouling caused by the build-up of microorganisms, algae, marine plants and life puts the delicate balance of our fragile marine eco-system at serious risk. The IMO calls invasive species “one of the greatest threats to the ecological and economic well-being of the planet”. Greater responsibility is being placed on ship owners and operators to manage their vessels better to reduce the impact of shipping on the environment.

A growing number of local port authorities, including those in the United States, New Zealand and Australia, are implementing stringent measures that ships must comply with before they are permitted to enter into their port waters. Prior to a vessel’s arrival, ships are being asked to prove their hull husbandry is properly managed. Energy efficiency management is becoming common place as are demands to keep and produce records of fuel consumption, when cleaning last took place and where the vessel has been idle or steaming.

Hull inspections are expected to increase, and if a vessel has higher than acceptable levels of hull fouling, port authorities can request the owners or operators to take measures, at their own cost, to clean the hull offshore before entry. Worse, they may even deny entry.

“To date, adherence to guidelines from regulatory bodies such as the IMO Biofouling Guidelines to minimise the transfer of invasive marine species has been largely optional for vessel owners and operators,” says HullWiper’s Managing Director, Simon Doran. “But the shipping industry is changing its approach and the steps taken to counter the harmful effects that biofouling cause on our oceans and environment. More and more port authorities are implementing mandatory regulations that all vessels must adhere to.”

Caption

Changing course

HullWiper’s Remotely Operated Vehicle (ROV) offers ship owners and operators with a compliant solution seeking the benefits of a clean hull with sustainable results and at an affordable price. The design and features of the ROV are based on results of HullWiper’s year-long consultation and survey with major shipping lines to determine what they thought would be the best development for existing hull cleaning services.

HullWiper uses adjustable high-pressure seawater jets to collect biofouling instead of being discharged back into the sea. The captured residues are pumped into a unique filter unit for safe and ecologically-approved disposal onshore. The ROV is designed to clean up to 1,500m² per hour, day or night, and in most weather conditions. No divers are involved, so cleaning can be done whilst operations are underway, eliminating the need for expensive down-time and extended port calls.

“Studies show that a clean hull can improve vessel speed, enhance long-term operating efficiency and create savings of up to 40% on fuel consumption per voyage. In addition to the financial benefits of a clean hull, it will also have a direct impact on lowering CO2 carbon emissions,” adds Mr Doran. “HullWiper is well positioned to deliver on these key focus areas.”

All HullWiper operations are in line with IMCA and IMO guidelines, and carried out in accordance with local legislation.

Caption

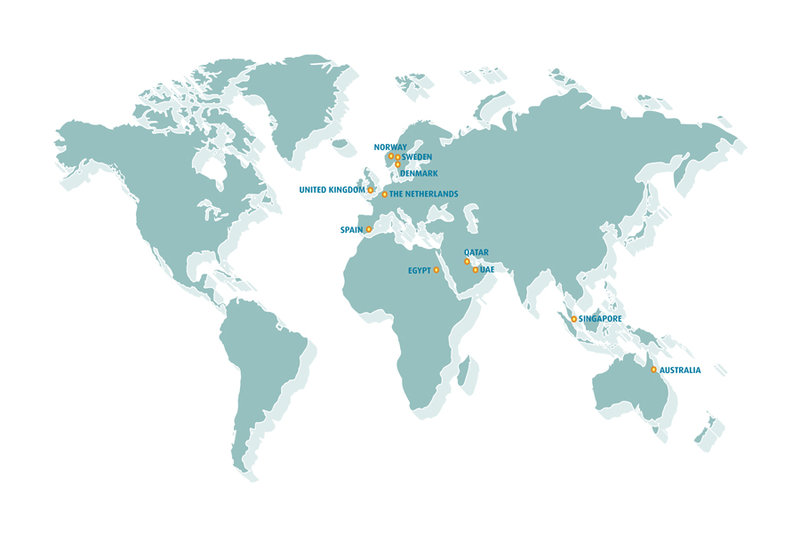

Global presence

In a bid to make HullWiper technology available to ship owners and operators at ports around the world, the company is seeking suitable partners to join the HullWiper network and lease an ROV. By adding the HullWiper to their portfolio of services, leasing partners stand to reap the benefits of having the tools at their disposal to comply with regulations, and offer a safe, around-the-clock and cost-effective hull cleaning and inspection service.

“We have also introduced the HullWiper Onboard Solution,” says General Manger Laurance Langdon. “A cruise liner, superyacht or O&G drill ship, for example, could place HullWiper on deck or build the ROV into their design plans using a door or hatch in the side of the hull or even, for the more adventurous, through a moon pool. The ROV could then be used for short periods when convenient to maintain hull coatings and keep them foul-free.”

HullWiper has been granted permission to operate within port waters at multiple locations worldwide including Sweden, Norway, Denmark, Singapore, Spain, Netherlands, Egypt, Australia, UK, United Arab Emirates and – on an ad-hoc basis – at key locations across the Middle East.

For more information on what HullWiper can do for you and your fleet, go to the website below.

POOR PLANNING AND OVERCONFIDENCE: THE MAIB’S MAIN FINDINGS

If there is one takeaway point from the inquiry it is that poor planning was at play.

Investigators discovered the lead pilot had not informed the bridge team of his plan for the turn around Bramble Bank. There was an “absence of a shared understanding of the pilot’s intentions for passing other vessels or for making the critical turns during the passage”.

Elsewhere, the master and port pilots were blamed for “complacency and a degree of over-confidence”.

There was an “absence of a shared understanding of the pilot’s intentions”

CMA CGM, which took delivery of the Vasco de Gama in July 2015, has acknowledged MAIB’s findings, and claims to be addressing the aforementioned issues raised in the report.

“Following this grounding, CMA CGM and ABP [Associated British Ports] Southampton have been working together,” said a spokesperson for the company in an email.

“As mentioned in the MAIB official report, CMA CGM has already taken measures to prevent this type of incident to happen again. CMA CGM is strongly committed to ensuring the safety of its operations and its crews in accordance with local and international regulations.”

All straight-bat stuff. ABP could not be reached for comment.

Unavoidable inquiry: why the MAIB inquiry needed to happen

Simon Boxall, a maritime expert from the University of Southampton, believes MAIB’s findings to be fair, despite Bramble Bank’s reputation as “a navigation hazard” due to it susceptibility to “slight movement after major storms”.

“Looking through the report there was no evidence of unforeseen mechanical failure on the ship, nor of abnormal weather conditions,” he says.

“On that basis, the two pilots and the ship’s master should have been in a position to safely navigate the vessel into port. It would appear to be user error – which is what the report says in so many words.

Introducing ways of reducing user error can only be seen as a good move

“In light of this, introducing ways of reducing user error can only be seen as a good move.”

Boxall also acknowledges things could have been a lot worse. As the Vasco de Gama was re-floated relatively quickly, the port didn’t suffer any kind of blockage – which, given the vessel’s size, would have brought Southampton to “a standstill”.

Neither did the vessel endure any serious damage. Nonetheless, an investigation was still necessary.

“If reports such as this are not produced then the safe navigation of shipping is not improved,” says Boxall.

“In the same way an airline near-miss is thoroughly investigated, it is important that the same is done for shipping – not as a witch hunt, but as a fact finding investigation to improve safety.”

Svein Kleven is senior vice president of engineering and technology for Rolls-Royce. Image courtesy of Rolls-Royce